The pics below illustrate just how vibrant and viable SouthEast Lights seeds are. The first one shows two seedlings that I didn’t use, that were left in the damp paper towel, for over a week, in complete darkness. The next one is a survivor sprout that I discovered next to the house, right next to the dirt pile. The last one I found when I went to the north side of the house where the recycled dirt is kept. I had no earthly idea this plant even existed, it grew that way totally on its’ own, with no human intervention. That plant is the pistallate basis for my current F12 generation of SouthEast Lights.

One thing I’m certain about after all these years of developing cannabis is; if you take care of the plant, it will take care of you. Most growers tend to forget that a cannabis plant is a living thing, that responds not only to its “breeding” but to the environment as well. That’s why I have _never_ understood why growers top, FIM, pinch, or otherwise abuse their plants “cause I’ll get more yield”. If you’ve ever actually observed a healthy, vigorous cannabis plant after it’s been topped, you can visually tell it adversely affects the plant. It just kinda sags and growth slows dramatically. I think I could effectively argue that the quality of the “high” you get from these types of plants is gonna suck, just like industrially grown cannabis purchased at a dispensaries.

But that time is not right now because this entry is going to be about how I don’t coddle, baby or otherwise spoil my cannabis plants. One thing I learned from Vic High’s work with Blueberry is I did _not_ want a plant that was fragile, required a perfect environment or was overly sensitive to common fertilizers.

So early on I set out to treat my cannabis plants just like the “weed” that it is. I allowed the soil I use to go through extensive wet to dry cycles. Speaking of soil, after a couple grows with expensive “organic” potting soil back in the early 2000’s, I decided to just use cheap, commonly available, peat based potting soil. After trying many “organic” fertilizers and various combinations of worm casings, bat guano and eye of newt or whatever other miracle product that was pushed back in the 90’s, I decided to keep it simple and use Peters (now Jacks) 20-20-20 fertilizer. I gave them as much light as possible and put that light as close as possible to the canopy. I’ve always provided as much air circulation around the plants, not only to exhaust heat and humidity, but to provide additional CO2 uptake and O2 discharge at the leaf level.

Most growers would be mortified at how brutal I have been with not only clones but sprouts as well. I'm reminded of a Saturday Night Live skit from the 70's comparing Lamaze birthing with SNL's version, which were just a wee bit different. No sterile cuttings of clones, no reduced lighting during germination or rooting, no support poles or netting, none of that bullshit that treats cannabis like a violet instead of hops. SouthEast Lights is a fucking Terminator version of cannabis that will take whatever abuse, neglect or mismanagement a dumbass grower can give and still survive.

The Current Hardware Environment

The equipment I use to develop cannabis has changed rather dramatically over the years. From the 1000 watt metal halide light I bought back in 87 up to the 8 inch inline carbon pre-filter purchased last week, I’ve used a staggering amount of hardware in my development of SouthEast Lights. There always seems to be some new equipment or technology available that tempts cannabis cultivators to update and upgrade their equipment. For the time being, I’m quite satisfied with what I’m using now, so it’s a good time to document what I’m using and why I’m using it.

Beginning with lighting, I use Spider Farmer SF4000 and SF2000 SMB (surface mounted board) LED lights in the basement tents and ViparSpectra XS4000 for the upstairs clone/seedling closet. One thing I learned about LED lighting early on is that heat is the primary determining factor on the longevity of these fixtures. They need to be kept as cool as possible. Since SMB LEDs utilize passive cooling via aluminum heatsinks, they have no cooling fans like the first gen blurple lights did. The aluminum can get rather hot to the touch, so I decided to utilize USB fans mounted on each end of the SMB’s to keep the heatsink and power supply as cool as possible. The USB fans consume minimal electricity, are quite cheap and are a low cost insurance policy to increase the lifespan of the LED’s and power supply. I’m also diligent about cleaning the heatsink by wiping it down with a slightly damp washcloth. This keeps dust and dirt (great thermal insulator) from building up.

Adequate ventilation of cannabis plants is just as vital to success as water, sunlight, soil and fertilizer. I use AC Infinity Cloudray A6 Clip Fans on every support post of my tents, and they are always set to Max speed. These are EC motors that utilize a brushless DC motor. They are more efficient than conventional fans, can consume up to 70% less energy, and most important to me, they are much less of a fire hazard than standard fan motors. Notice the fan placed underneath the canopy? You have to provide air circulation to the main stem and branches as well as the canopy, if you want to prevent powdery mildew and botrytis. I don’t use the available wireless controller for the fan nor do I have an app to control them. That just adds a layer of complexity that I really don’t need. The $30 thermometer/hygrometer with 3 sensors and alarms gives me all the info I need. I monitor the intake temp/humidity from tent #1 and tent #2 (which are connected by dual 8” ducting) and the exhaust data from the air going into the carbon filter.

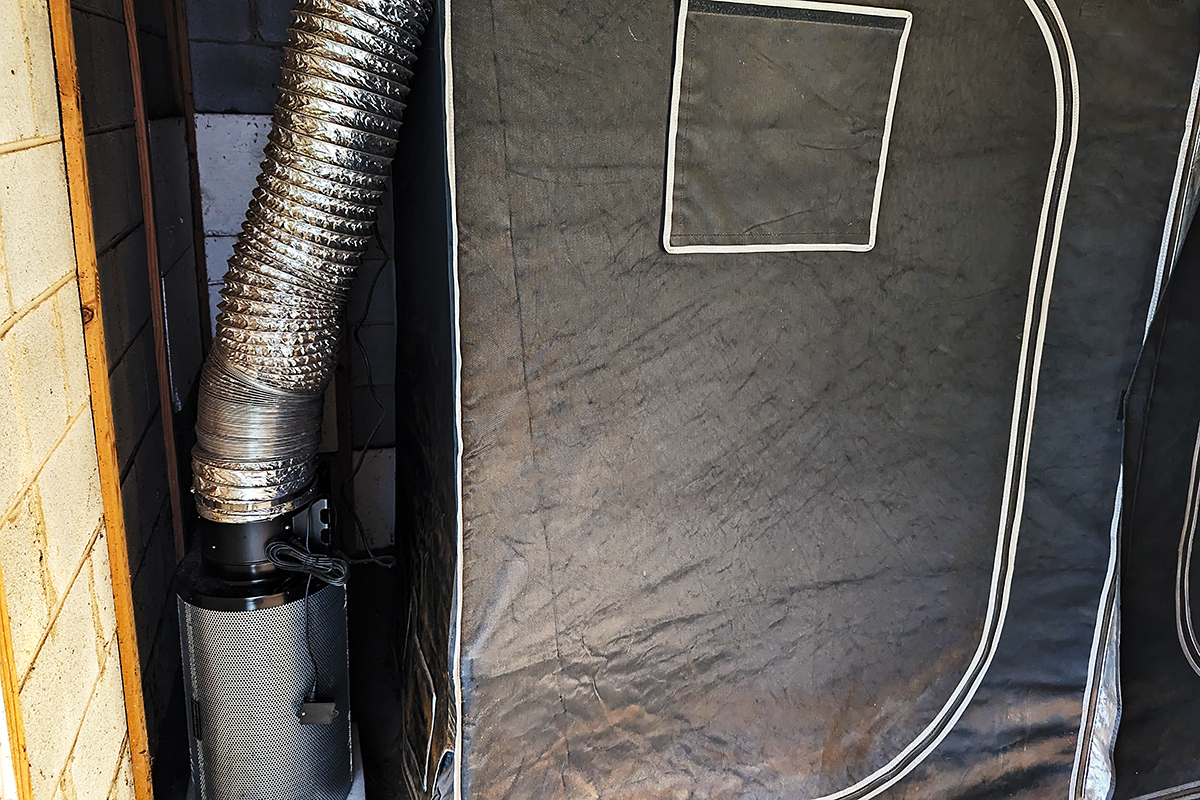

I use an 8” TerraBloom filter with their associated EC exhaust fan to evacuate the tent air. TerraBloom was the first company to utilize EC technology, they have a 3 year warranty that I had to use when a power surge from a summer storm took it down. I told the rep I wasn’t sure if it was the surge that took it out or whether it just failed and they replied something to the effect, “… if it’s not working. it’s not working, we’ll send you replacement.” Can’t beat that customer service and they now have a customer for life. I’ve never understood why most growers put the carbon filter and exhaust fan _inside_ the tent? I have both the main carbon filter and exhaust fan located outside of the tent so it sucks air out rather than pushing it out. Notice the filter attached to the tent outlet? That filters out dust/dirt before it can reach the interior of the carbon filter and clog it up.

For the first time in a very long time frame, I don’t have tech lust for something new in the tents.

What I'm Trying To Accomplish

I’ve never set specific goals to accomplish with the developmental work I’ve done with Sensi’s original Northern Lights, always just wanted to make it better. I select parental units based primarily on structure and vigor, rather than resin production or smell. Since I’ve been self-sufficient with cannabis for a very long time now, it has given me the freedom to experiment without fear of failure. Show me a grower who has never had a bad harvest and I’ll show you a grower who has never accomplished anything extraordinary.

Botrytis (bud rot) has been a major problem with the tents in the basement, especially during harvests in the late summer or early fall. The basement is 2200 square feet of un-partitioned, unheated space, where the temp is usually between 75-85 degrees and the relative humidity between 80-90 percent. Not going to get into the specifics of VPD (vapor pressure deficit) but this is an ideal environment for the development of botrytis. With the big, donkey dick like buds the Type II/Indica dominate plants have, a summer harvest almost guarantees botrytis.

So I decided to use an almost entirely Type II/Indica staminate plant I had saved pollen from last year and use it to fertilize a particularly aggressive branching Type IV/Hybrid plant that I’ve cloned for several generations now. I’m trying to develop a plant that has the large, dense colas typical of Type II/Indica plants but with the aggressive, branching characteristics of the Type IV/Hybrid clone. I want a candelabra shaped plant with large, dense colas hoping that will be resistant to the development of botrytis and powdery mildew.

Journal Grow On The Move

The Journal grow has progressed quite nicely in the clone closet, so it’s time for them to move on up, or in this case, down to the basement tents. I always start out seedlings in 3X3X8 inch plastic pots because I want the developing root system to be driven down as deep as possible in its’ initial development. Then they get transplanted into fabric pots so the roots can expand outward from a deep, central core. I’ve written many times about fabric plant containers, so I won’t belabor the point yet again but there is simply no better container for the development of a robust root system for cannabis. At the end of this grow, I may sacrifice one of the containers, cut it off from the root ball, and rinse off the soil to illustrate the extensive root system that is developed with fabric containers.

In the next installment of this Journal, I’ll go over the equipment I’m currently using and what I do to make the lights, filters and fans last as long as possible. I’ll also give info on what I’m trying to accomplish with this particular combination of cannabis plants and try to summarize my overall philosophy of developing cannabis.